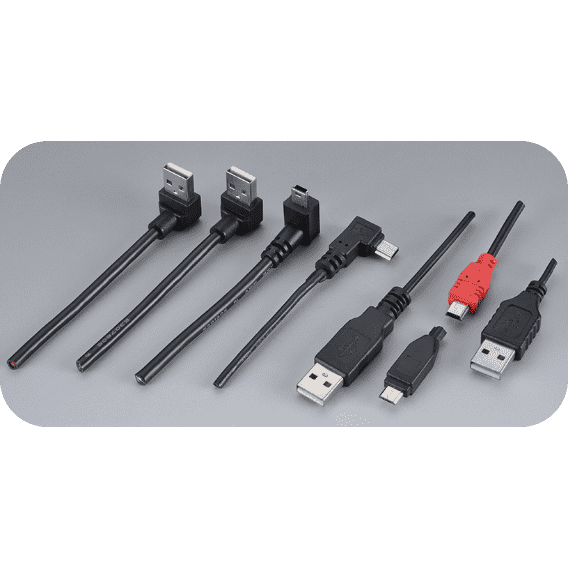

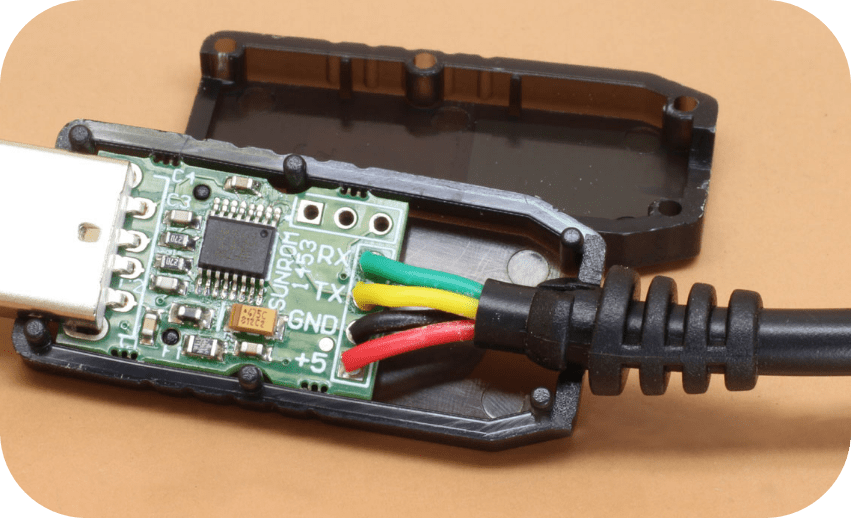

USB Connectors

Custom overmold tools for USB cable A type, B type, C type, Mini USB, Micro USB, male and female, straight and right angle, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

D-sub Connectors

Custom connector overmold tools for DB 9p, 15p, 25p, 26p, 37p, etc., male and female, straight and right angle, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

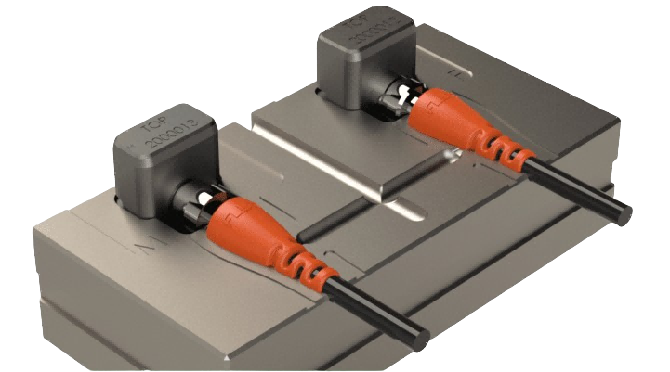

DC Power Connectors

Custom overmold tools for DC 5521, 5525, 3.5mm, male and female, straight and right angle, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

AMP connector

Custom overmold tools for TE AMP Superseal 1.5 series connector, male and female, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

Molex connector

Custom overmold tools for Molex 5557/5559, 43020/43025 series connector, male and female, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

Trailer SAE connectors

Custom overmold tools for Trailer SAE connector 1P, 2P, 3P, 4P, 5P, male and female, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

Power Connectors

Custom overmold tools for power connectors, current rate over 130A max, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

OBD II connectors

Custom overmold tools for OBD II connector, male and female, straight and right-angle, over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.

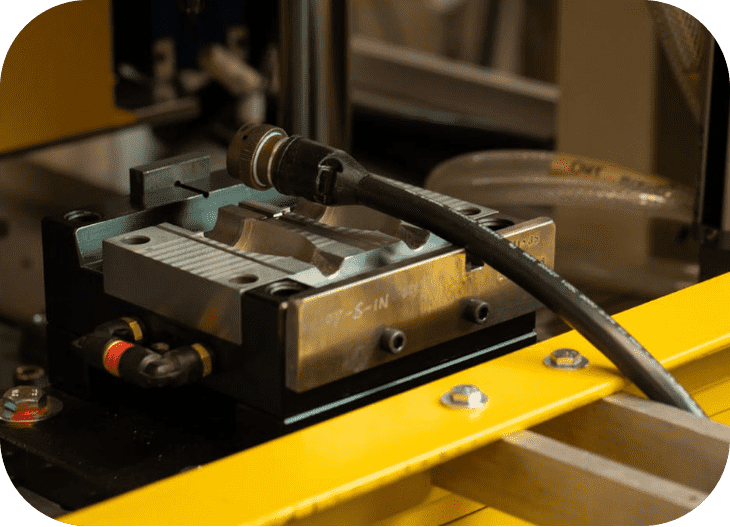

Other Special Connectors

Custom overmold tools for other special connectors, like sensors, battery, medical, etc., over-mold materials support PVC 45P and 60P, color support black, white, red, yellow, etc.