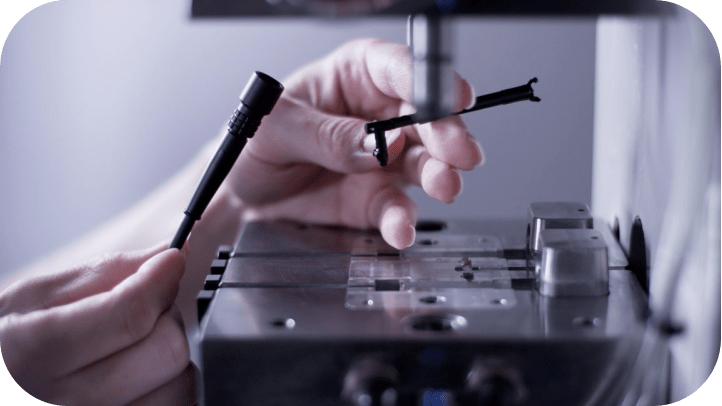

Custom Wire Harness Assembly

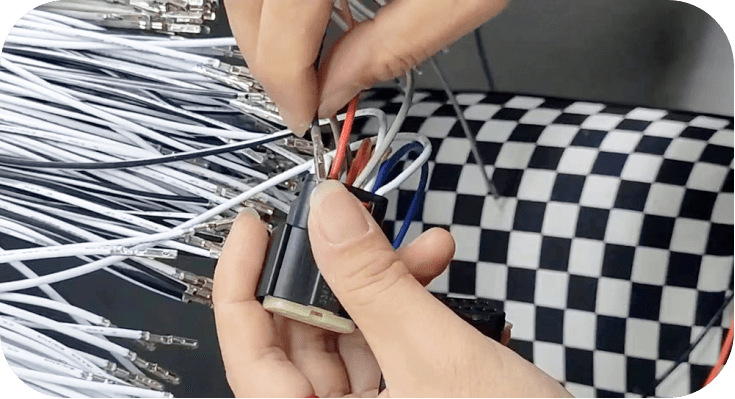

Custom Wire Harness Assembly refers to a tailored electrical wiring system designed to meet specific requirements and applications. This assembly typically organizes wires, cables, and other electrical connectors together to simplify installation, reduce space usage, and enhance the reliability and performance of electrical systems. custom wire harness Assemblies are commonly used in various fields, including automotive, aerospace, home appliances, industrial equipment, and communication devices.

Key Features:

1.Tailored Design: Custom wire harness assemblies are designed specifically to meet the unique requirements of each application, ensuring optimal fit and functionality.

2.High-Quality Materials: Made from premium materials to ensure durability, flexibility, and long-term performance.

3.Space Efficiency: Organized wiring reduces clutter and maximizes space efficiency in complex electrical systems.

4.Enhanced Reliability: Provides secure and reliable connections, reducing the risk of electrical failures and improving overall system reliability.

5.Simplified Installation: Pre-assembled harnesses simplify the installation process, saving time and reducing labor costs.

6.Versatility: Suitable for a wide range of applications, including automotive, aerospace, home appliances, industrial equipment, and communication devices.

7.Compliance with Standards: Manufactured to meet industry standards and regulations, ensuring safety and compatibility with various systems.

Applications:

1.Automotive Industry: Custom wire harness assemblies are extensively used in vehicles for connecting various electrical components such as engines, lights, sensors, and infotainment systems, ensuring reliable performance and ease of maintenance.

2.Aerospace Industry: These assemblies are critical in aircraft for connecting avionics, communication systems, and other essential electrical components, contributing to the safety and efficiency of aviation operations.

3.Home Appliances: Custom wire harnesses are used in household appliances like refrigerators, washing machines, and ovens to connect internal components, enhancing the functionality and reliability of these devices.

4.Industrial Equipment: In industrial settings, wire harness assemblies connect machinery and equipment, facilitating efficient operation and minimizing downtime due to electrical failures.

5.Telecommunications: They are used in communication devices and systems to ensure stable and efficient connectivity, supporting the smooth operation of telecommunication networks.

6.Medical Devices: Custom wire harnesses are utilized in medical equipment to connect various sensors, monitors, and control systems, ensuring precise and reliable operation in critical healthcare applications.

7.Consumer Electronics: These assemblies are essential in consumer electronics such as computers, gaming consoles, and smartphones, providing organized and efficient internal wiring solutions.

8.Renewable Energy Systems: Custom wire harnesses are used in solar panels, wind turbines, and other renewable energy systems to connect electrical components, supporting sustainable energy generation and distribution.

Advantages of Using Custom Wire Harness Assembly

1.Improved Efficiency: Custom wire harness assemblies are designed to fit specific applications perfectly, which simplifies the installation process and reduces assembly time, leading to increased efficiency.

2.Enhanced Reliability: By using high-quality materials and precise manufacturing processes, custom wire harnesses provide reliable connections, reducing the risk of electrical failures and improving overall system performance.

3.Space Optimization: Custom assemblies organize wires and cables neatly, reducing clutter and saving space, which is particularly important in compact or complex systems.

4.Cost Savings: Pre-assembled wire harnesses reduce the need for extensive manual wiring, lowering labor costs and minimizing the risk of errors during installation.

5.Customization: These assemblies can be tailored to meet specific requirements, ensuring compatibility with various components and systems, and allowing for greater design flexibility.

6.Enhanced Safety: Custom wire harnesses are designed to meet industry standards and regulations, ensuring safe operation and reducing the risk of short circuits, electrical fires, and other hazards.

7.Simplified Maintenance: With organized and labeled wiring, custom wire harnesses make it easier to troubleshoot and maintain electrical systems, reducing downtime and maintenance costs.

8.Versatility: Suitable for a wide range of applications across different industries, from automotive and aerospace to consumer electronics and medical devices.