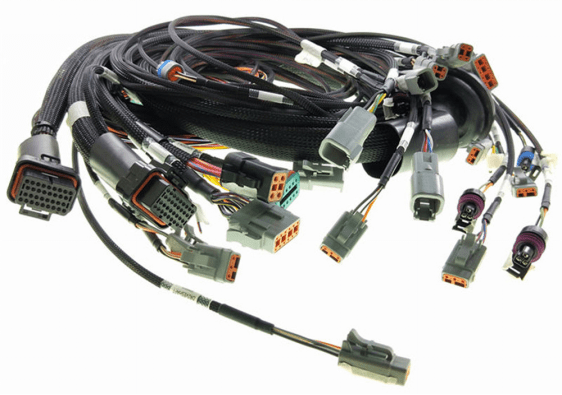

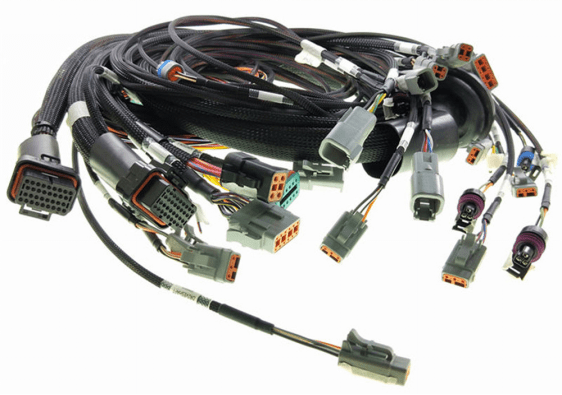

Custom Auto Wiring Harness

Custom Auto Wiring Harness is a set of automotive wires designed and manufactured according to specific vehicle or customer needs, used to connect various electrical and electronic components in the vehicle. It is responsible for transmitting power and signals to the vehicle's electrical system, connecting functional modules such as engines, lights, dashboards, air conditioning, audio systems, sensors, and safety equipment to ensure that they can work properly.

Unlike standardized wiring harnesses, custom automotive wiring harnesses are tailored to specific models, uses, or special needs of users, and are suitable for modified cars, racing cars, electric cars, or other vehicles with special electrical configuration requirements. Custom wiring harnesses can include a variety of unique design options, such as specific lengths of cables, additional connectors, heat-resistant or waterproof materials, and cable protection measures designed for different application scenarios (such as off-road, racing, or industrial vehicles).

Excellent heat resistance

Custom Auto Wiring Harness can operate stably in high temperature environments. It uses high temperature resistant insulating materials such as silicone rubber, polyimide or fluoroplastics, which can withstand temperatures of 150°C to 200°C or even higher, and is particularly suitable for high temperature areas near the engine compartment and exhaust system. In addition, Custom Auto Wiring Harness is equipped with a metal shielding layer or high temperature resistant sleeve to isolate the heat source and prevent high temperature damage. The heat-resistant wiring harness can not only withstand instantaneous high temperatures, but also has long-term thermal stability to avoid thermal aging or material degradation, ensuring the safe and reliable operation of the vehicle's electrical system.

Waterproof materials

Custom Auto Wiring Harness can operate stably in wet or harsh environments. The main waterproof materials used include high-performance polymers such as thermoplastic elastomers (TPE), PVC and silicone rubber, which can effectively prevent water penetration. In addition, waterproof connectors usually meet IP67 or IP68 standards, providing excellent sealing protection, and heat shrink tubing is used to seal key parts of the wiring harness to further enhance waterproof performance. Custom Auto Wiring Harness can maintain safe and reliable working conditions in wet environments in applications such as automobiles, electric vehicles, and ships.

Types of Wiring Harness in Car

In a car, there are several types of wiring harnesses, each designed to connect and manage specific electrical systems. Here are the most common types of wiring harnesses in cars:

Engine Wiring Harness: This connects the engine's electrical components, such as sensors, ignition system, alternator, fuel injectors, and starter motor, ensuring efficient engine operation.

Chassis Wiring Harness: Responsible for connecting various electrical components in the car’s chassis, such as lights, ABS system, and suspension components.

Dashboard Wiring Harness: This harness connects the dashboard's electrical systems, including the instrument cluster, gauges, air conditioning controls, and infotainment system.

Body Wiring Harness: It connects the electrical components related to the car body, such as power windows, door locks, mirrors, and lighting systems.

HVAC Wiring Harness: Specifically connects and controls the heating, ventilation, and air conditioning (HVAC) system components, including blower motors, actuators, and temperature sensors.

Battery Wiring Harness: This harness links the car’s battery to various systems that require direct power, such as the starter motor and alternator.

Tailgate Wiring Harness: This handles the electrical components in the rear section of the vehicle, including tail lights, reverse lights, and rear cameras.

Trailer Wiring Harness: Designed for towing, this harness provides connections for trailer lights, brakes, and turn signals.

Each wiring harness is vital for connecting specific systems in the car, ensuring efficient and safe operation of the vehicle’s electrical components.

FAQ

What are the main advantages of Custom Auto Wiring Harness?

Customized wiring harnesses can meet specific electrical requirements, adapt to different models and configurations, provide higher flexibility and performance, and ensure the stability and safety of the vehicle's electrical system.

What are the material options for Custom Auto Wiring Harness?

Commonly used materials include high-temperature resistant insulation materials (such as silicone rubber, PVC), water-resistant materials (such as thermoplastic elastomers) and corrosion-resistant metals to ensure the reliability of the wiring harness in harsh environments.

How to ensure the quality of Custom Auto Wiring Harness?

Choose Hooha Harness's rich manufacturer for strict quality control, including material testing, process monitoring and final product testing to ensure the durability and safety of the wiring harness.

Is the installation of Custom Auto Wiring Harness complicated?

Although the installation of custom wiring harnesses may be slightly more complicated than standard wiring harnesses, manufacturers usually provide detailed installation guides and support to ensure a smooth installation process.