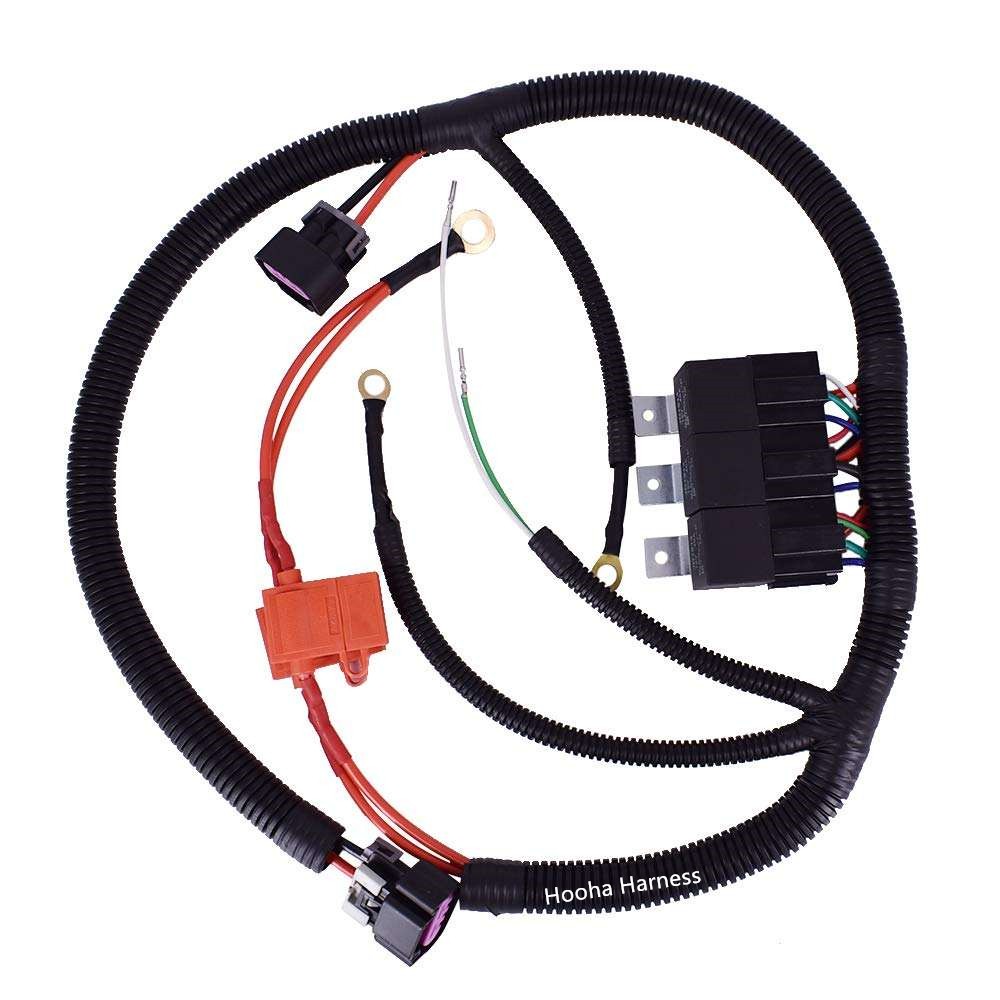

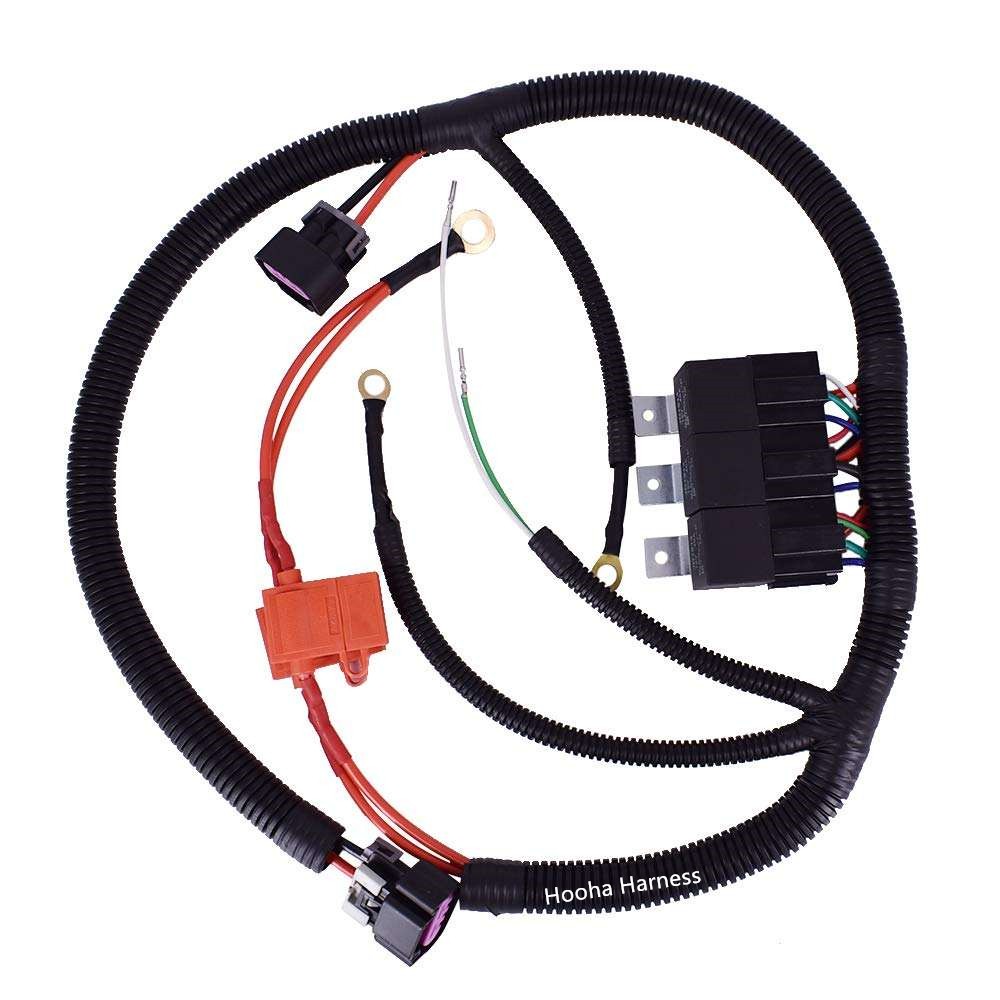

What is Cable And Harness Assembly?

Cable And Harness Assembly is an electrical assembly that combines multiple wires and cables in an orderly manner and wraps them with insulating materials or protective shells. They are designed for power transmission, signal transmission or data communication, providing efficient, safe and reliable electrical connection solutions. These components can optimize the wiring structure of the equipment, reduce failure points, and ensure long-term stable operation of the equipment.

As a professional Cable And Harness Assembly Manufacturer, Hooha Harness is committed to producing high-performance cables and harness assemblies that meet international quality standards, serving multiple fields such as automotive, aerospace, industrial automation, and medical equipment, and can provide customized solutions according to customers' specific needs.

Features of Cable and Harness Assemblies

Highly customized

Design different lengths, connector types and wire specifications according to equipment requirements to flexibly meet diverse needs.

Excellent mechanical protection

Protect the wires from physical damage, chemical corrosion and environmental factors through an external sheath.

High reliability and durability

Use high-quality conductors and insulation materials to ensure long-term stable operation and suitable for various harsh environments.

Compactness and space optimization

The centralized harness design simplifies the internal wiring of the equipment, saves space and reduces installation complexity.

Electromagnetic compatibility (EMC)

The efficient shielding design can effectively suppress electromagnetic interference and ensure the integrity of signal transmission.

Strong environmental adaptability

It can withstand harsh environments such as high temperature, humidity, vibration and impact, and is suitable for industrial and outdoor scenes.

Easy to install and maintain

The modular design and standardized interface significantly improve the efficiency of installation and maintenance.

Functions of cable and harness assemblies

Power transmission

Provide power input and power distribution for the equipment to ensure the normal operation of the equipment.

Signal transmission

Transmit control signals and data between different modules to provide support for the intelligent operation of the equipment.

Data communication

Real-time data transmission is completed through high-speed transmission cables, which is widely used in the fields of communication and computers.

Electrical protection

Provide multi-layer insulation and shielding to prevent short circuits, electromagnetic interference and static electricity.

Mechanical protection

Prevents wires from being damaged by friction, bending or external force, thereby extending the service life of the product.

Simplified equipment wiring

By orderly integrating wires, simplifying the internal cable management of the equipment, and improving the overall aesthetics and convenience of operation.

Application fields of cable and harness assemblies

Automobile manufacturing

Applied to in-vehicle wiring harnesses, electric vehicle battery pack connections, lighting systems and entertainment systems, etc.

Aerospace

Connect aircraft navigation, power, communication systems and other equipment to provide high reliability and safety.

Communication and network

Used for data transmission and network connection in base stations, data centers and communication equipment.

Medical equipment

Used for electrical connection and signal transmission of diagnostic instruments, monitoring equipment and treatment devices.

Industrial automation

Applicable to robots, CNC machine tools and factory automation systems to ensure efficient operation of equipment.

Household appliances

Applied to internal wiring of refrigerators, air conditioners, washing machines and other appliances to provide safe and reliable electrical connections.

Renewable energy

Cable connections for solar panels and wind power generation equipment to improve energy efficiency.

How to maintain and maintain cables and harness assemblies

Regular inspection

Regularly check the appearance of the harness assembly for cracks, wear or aging, and replace it in time if problems are found.

Cleaning and maintenance

Use a soft cloth to clean the outer sheath to avoid dirt and chemical accumulation that affects its performance.

Avoid excessive bending

Avoid excessive bending of cables during installation and use to prevent internal conductor breakage or insulation damage.

Protect connectors

Ensure that the connector plug and socket are tightly combined to avoid looseness or poor contact.

Adapt to environmental requirements

In high temperature, high humidity or corrosive environments, select harnesses made of specific materials to ensure their durability.

Regular performance testing

Use professional testing instruments to detect conductivity, insulation resistance and anti-interference performance to ensure that they meet the needs of the equipment.

Properly store spare components

Unused cables and harness components should be stored in a dry and ventilated environment to avoid damage from high temperature and moisture.

Precautions for using cable and harness components

Correct selection

Select the appropriate cable and harness type according to the electrical parameters of the specific equipment and the use environment.

Pre-installation inspection

Before installation, confirm that the components have no external damage and that the performance meets the requirements to ensure that they can operate normally.

Follow standard operations

Install and maintain according to the operating manual provided by the manufacturer to avoid damage caused by incorrect operation.

Prevent overload use

Ensure that the current and voltage operate within the rated range to prevent safety problems caused by overload.

Avoid external damage

Prevent sharp objects from scratching the outer sheath or excessive mechanical stress from causing cable failure.

Regular updates

Components that are aged or have exceeded their design service life should be replaced in a timely manner to avoid unexpected failures.

Environmental protection

When working in extreme temperature, humidity or chemically corrosive environments, use additional protection measures such as waterproof connectors or shielding layers.

As a professional Cable And Harness Assembly Manufacturer, Hooha Harness has rich experience and technical accumulation in the industry and is able to provide a variety of cables and harness assemblies to meet the complex needs of different fields. Through advanced manufacturing processes, strict quality management and flexible customization services, Hooha Harness always provides customers with high-quality and high-reliability solutions. In practical applications, regular maintenance and reasonable use are the key to ensuring the long-term performance of cable and harness assemblies, helping companies improve equipment efficiency and reduce operating costs.