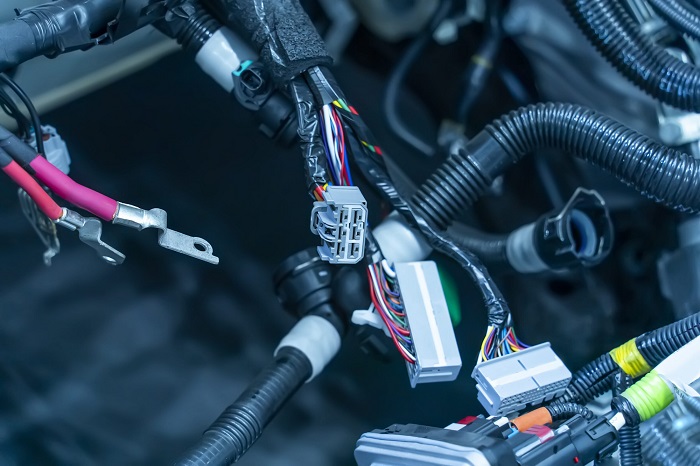

In the automotive industry, wiring harnesses play a crucial role in ensuring the smooth operation of electrical systems within a vehicle. An automotive wiring harness is a group of electrical cables or wires that transmit signals and power to various electrical components within a car. Hooha Harness is a leading automotive harness assembly supplier specializing in providing high-quality wiring harness solutions for the automotive sector. As one of the top OEM wiring harness manufacturers, Hooha Harness is committed to offering superior wiring harnesses that meet the highest industry standards, ensuring the safety, reliability, and performance of modern vehicles.

Features of Automotive Wiring Harnesses

Automotive wiring harnesses are designed to meet the specific needs of automotive electrical systems, from power transmission to signal communication. The key features of a well-designed automotive harness assembly include:

Durability and Longevity: Automotive wiring harnesses are designed to withstand harsh environments, including exposure to high temperatures, moisture, oil, and chemicals. High-quality materials like cross-linked polyethylene (XLPE) insulation and nylon sheathing are often used to enhance durability.

High Conductivity: To ensure minimal power loss, the wires within the harness are made of high-quality copper or aluminum, offering excellent electrical conductivity.

Compact and Lightweight: Modern vehicles demand wiring harnesses that are not only reliable but also compact to save space and reduce weight, contributing to better fuel efficiency and improved vehicle performance.

Custom Fit: Hooha Harness provides customized car wiring harnesses tailored to meet the specific design and functional requirements of individual car models. These are manufactured based on detailed automotive blueprints and specifications.

Safety Compliance: All products comply with international safety standards, including ISO 9001 and IATF 16949 certifications, ensuring that they meet stringent quality and safety protocols.

Advantages of Automotive Harness Assembly

Cost-Effective Solution: Choosing a professional automotive harness assembly supplier like Hooha Harness enables automakers to lower costs by streamlining the supply chain. Manufacturers can obtain high-quality, reliable harnesses at competitive prices, making them cost-effective solutions for large-scale production.

Improved Reliability: As automotive wiring harness production is carried out using advanced manufacturing techniques and automated systems, the reliability of the final product is guaranteed. This ensures that all electrical systems within the vehicle function as intended over the long term, reducing the risk of failures that could lead to costly repairs.

Customization Flexibility: As one of the leading vehicle wiring harness manufacturers, Hooha Harness offers the ability to customize wiring harnesses based on specific vehicle models, making them adaptable to various designs, power requirements, and environmental conditions. Whether it's for a luxury car, electric vehicle (EV), or a commercial truck, Hooha Harness can provide the perfect fit.

Fast Delivery Time: Thanks to a robust supply chain and efficient manufacturing processes, Hooha Harness is able to provide automotive harness assembly suppliers with fast turnaround times, ensuring that production schedules are met without compromising quality.

Applications of Automotive Wiring Harness Assemblies

The application of automotive wiring harness assemblies spans various segments of the automotive industry, including:

Passenger Vehicles: Wiring harnesses in passenger vehicles are essential for connecting various electrical systems such as lighting, infotainment, safety systems (airbags, anti-lock braking), and powertrain electronics.

Electric Vehicles (EVs): EVs require specialized wiring harnesses to manage their high-voltage battery systems, electric motors, and charging infrastructure. Hooha Harness offers solutions for both high-voltage and low-voltage EV wiring harnesses, ensuring efficient power management.

Commercial Vehicles: Larger vehicles such as trucks, buses, and delivery vans use heavy-duty wiring harnesses to support complex electrical systems including lighting, air conditioning, sensors, and entertainment systems.

Specialty Vehicles: Off-road vehicles, agricultural machinery, and construction equipment also rely on robust automotive wiring harnesses to power equipment and instruments designed for extreme conditions.

Autonomous Vehicles: With the rise of autonomous driving technologies, advanced wiring harnesses are critical for integrating sensors, cameras, radar, and communication systems required for autonomous operation.

Customization Considerations for Automotive Harness Assemblies

At Hooha Harness, customization is key to meeting the exact needs of each vehicle manufacturer. Below are some critical factors for automotive harness assembly customization:

Wire Length and Gauge: Depending on the vehicle's size and layout, wiring harnesses must be made to precise lengths and wire gauges. Custom wire lengths are especially important in modern vehicles with increasingly complex electrical systems.

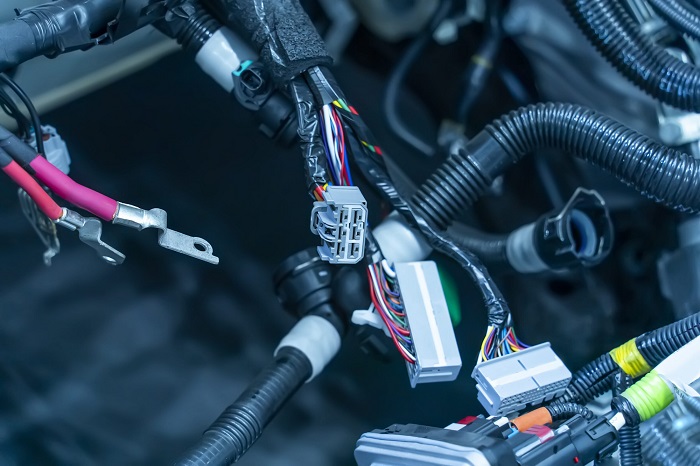

Connector Types: The choice of connectors, which link the wires to various vehicle components, can vary based on the type of system being supported. Hooha Harness offers a range of connector types, including those for high-current, signal, and power transmission, ensuring compatibility with the overall system.

Insulation and Shielding: Different vehicles may require specialized insulation and shielding to protect against electromagnetic interference (EMI) and to meet environmental requirements such as water resistance or high-temperature resistance.

Color-Coding and Marking: For easy identification and maintenance, custom car wiring harnesses are often color-coded or marked with specific labels to help technicians during installation and repairs.

Compliance with Standards: Depending on the market, automotive wiring harnesses must comply with various industry standards (e.g., SAE J1128, ISO 16750) and regional regulations (e.g., UL, RoHS). Hooha Harness ensures all custom wiring assemblies meet these standards for performance, safety, and environmental impact.

Usage Precautions for Automotive Wiring Harnesses

To maximize the longevity and efficiency of automotive wiring harnesses, certain precautions must be taken during installation and usage:

Proper Installation: Ensuring the wiring harness is installed correctly is critical. Wires should be routed away from sharp edges, high-heat areas, and moving parts to prevent wear and tear. Proper securing with clips or mounts is essential to prevent strain on the wires.

Avoid Overloading: Overloading electrical circuits can damage the wiring harness and lead to system failure. Ensure that the harness is designed to handle the specific power demands of the vehicle’s systems.

Regular Inspections: Periodically inspect the wiring harness for signs of wear, fraying, or corrosion. Electrical connectors should also be checked for tightness and any signs of loose connections.

Waterproofing: Many automotive wiring harnesses are exposed to moisture, especially in vehicles that operate outdoors or in wet conditions. Ensure that any custom harness is equipped with proper waterproofing, and avoid submerging electrical components in water.

Heat Management: Over time, high temperatures can degrade insulation and cause the wires to lose their protective qualities. Ensure the wiring harness is rated for the temperatures encountered in the engine bay or other hot areas.

Hooha Harness, as a top automotive harness assembly supplier, offers cutting-edge solutions tailored to meet the demanding requirements of the automotive industry. With a focus on quality, customization, and cost-efficiency, Hooha Harness ensures that manufacturers receive top-tier vehicle wiring harnesses that support the safe and efficient operation of vehicles. Whether you’re an OEM looking for car wiring harness makers or seeking advanced solutions for automotive wiring harness production, Hooha Harness has the expertise and technology to meet your needs.