200+ professional skill people work for your projects

- Home

- About Us

-

Services

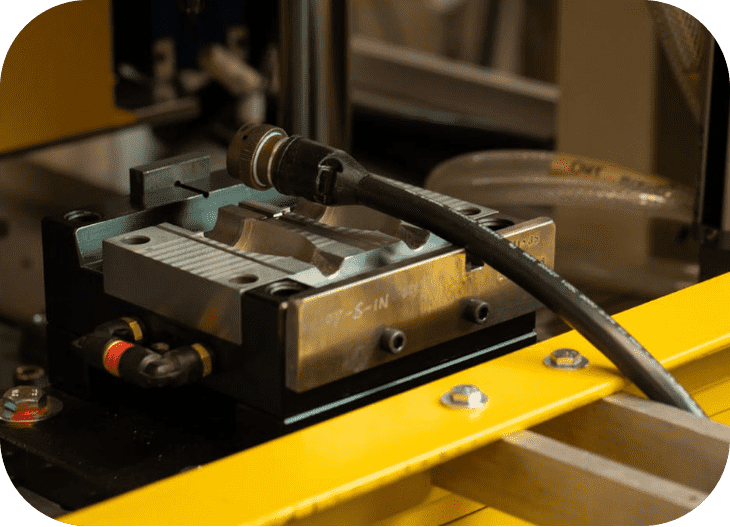

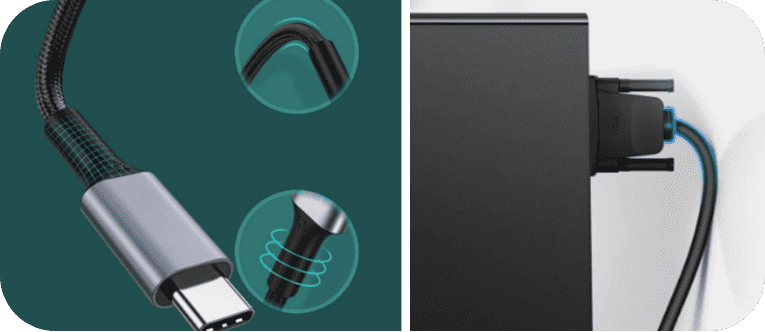

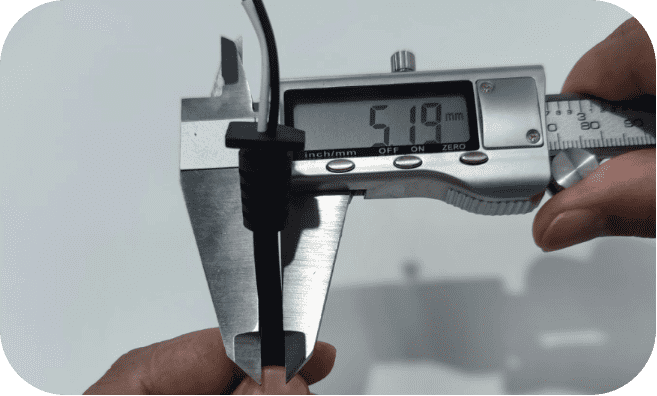

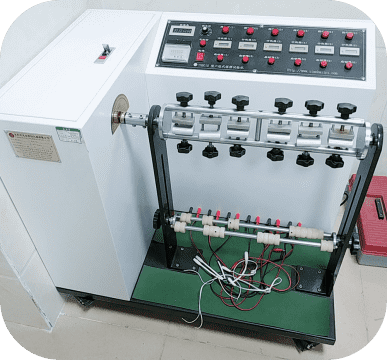

- Automotive wire harness assembly

- Molex wire harness assembly

- JST wire harness ssembly

- Deutsch wire harness assembly

- Trailer wire harness assembly

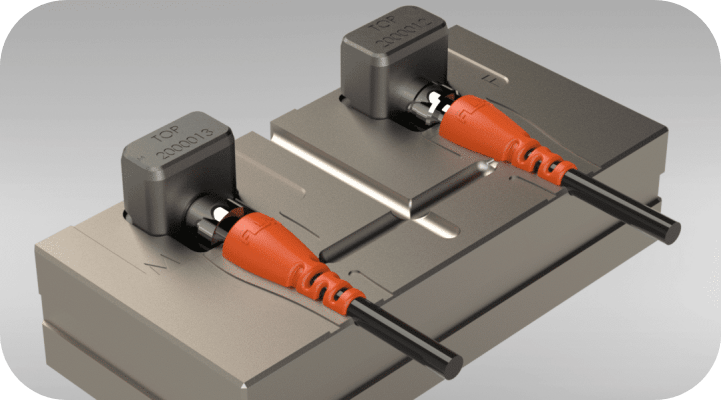

- Coil cable assembly

- Flat ribbon cable assembly

- E-bike wire harness assembly

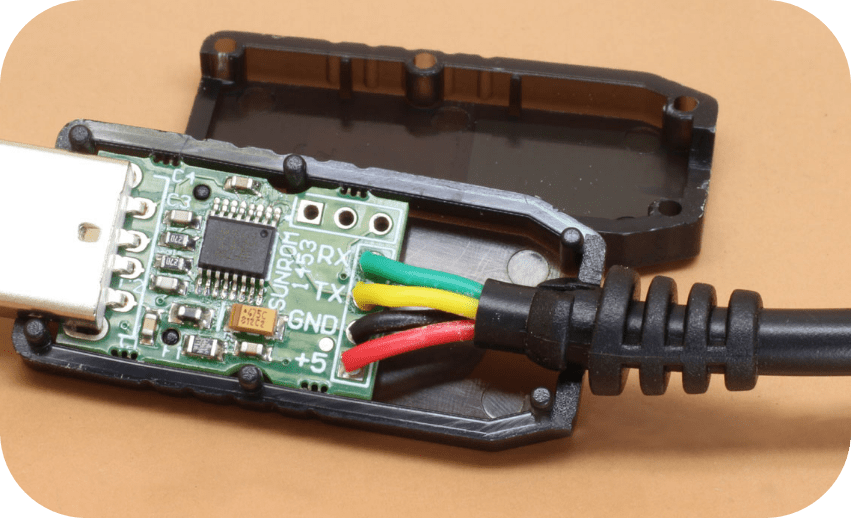

Custom wire harness assembly

-

Gallery

- Automotive wire harness assembly

- Molex wire harness assembly

- JST wire harness ssembly

- Deutsch wire harness assembly

- Trailer wire harness assembly

- Coil cable assembly

- Flat ribbon cable assembly

- E-bike wire harness assembly

Custom wire harness assembly

- Videos

- Blogs

- Contact Us

Language